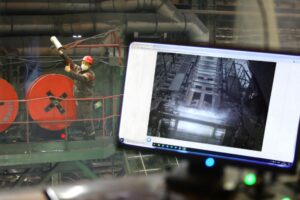

“Zaporizhstal” systematically working at the product quality improvement. With that in mind, video monitoring has been installed in the thin sheet hot-rolling mill shop. The online video monitoring allows controlling the quality of coil winding and preventing product defects.

“Product quality management is as a continuous process as its production. It is important to notice that our products continue to be in demand with consumers, so we are constantly improving the existing quality control system,” said Alexander Mironenko, Director General of “Zaporizhstal” PJSC.

According to the ongoing program, aimed to improve the quality of products, on coiler No. 1 and No. 2 of NTLS-1680 in the thin sheet hot rolling mill shop, were installed additional cameras that constantly monitor the winding process in real time. This allows the mill operators quickly eliminate deviations, reducing the possibility of the defects formation such as bended edge and impressions. The expected effect is a decrease in the formation of these defects by 20% in the total volume of finished products.

It should be noted that special working groups were created at “Zaporizhstal” Works aiming to identify and eliminate top-defects of rolled stock. Each working group monitors the causes of defects divided into metallurgical, rolling, and relating to the equipment operation. After a thorough analysis of the defects formation causes, laboratory and industrial tests are carried out, and then practical measures are introduced to improve the quality of products and eliminate the defects.

In 2019, “Zaporizhstal” has successfully passed the second supervisory audit of the Integrated Management System for compliance with the requirements of International quality management standards ISO 9001: 2015.